THE CHALLENGE:

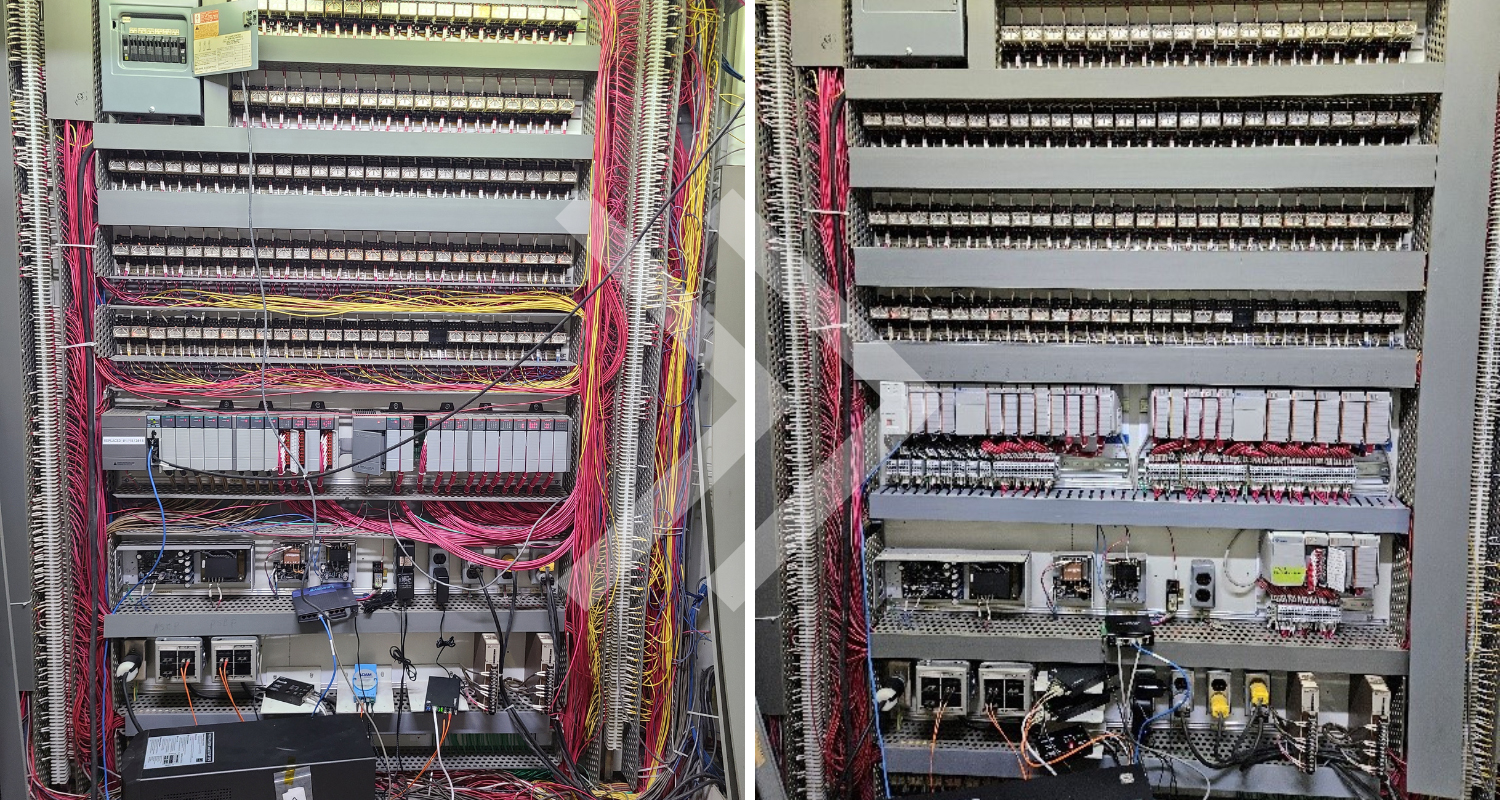

The primary challenge was to enhance a time-based palletizing machine to increase throughput and eliminate the necessity for constant operator supervision. Laticrete, a global leader in building material manufacturing, was facing frequent system jams, which required an operator to be stationed at the system to fix jams approximately every other pallet. These jams took around seven minutes to resolve, severely impacting the efficiency, as it took less than ten minutes to build a pallet when the system was operational. The system, originally controlled by an older CompactLogix PLC converted from an SLC500, lacked the original PLC program, leaving only bit register programming without nomenclature, further complicating the task.

KEY ACHIEVEMENTS:

- Implementation of Event-Driven Logic: By reprogramming the side-to-side shifters using ladder logic programming, the project successfully replaced the existing time-based system with event-driven logic. This change allowed the system to adapt to varying product sizes without manual timer adjustments, enhancing the robustness and flexibility of the palletizing process.

- Reduction of System Jams: The new logic significantly reduced the occurrence of system jams, eliminating the need for an operator to be constantly present. This was achieved by blocking existing timers and implementing event-driven release mechanisms, ensuring products entered the palletizer with the correct spacing.

- Increased Throughput: As a direct result of the implemented changes, Laticrete’s throughput increased from approximately 45-50% to over 89%. This improvement was sustained over six months without experiencing double product feeds or jams due to the side-to-side shifters.

- Operational Efficiency: The elimination of frequent jams and the need for constant operator intervention allowed personnel to focus on other critical tasks, further improving overall plant efficiency.

FUTURE OPPORTUNITIES:

- Replication of Success: Due to the success of this project, Laticrete has requested similar implementations in their other plants. This presents an opportunity to standardize event-driven logic across multiple locations, further enhancing operational efficiency and throughput on a larger scale.

- Continuous Improvement: The project demonstrated the superior adaptability of event-driven logic over time-based logic. This opens avenues for continuous improvement and innovation in industrial control systems, ensuring they remain responsive to changing production requirements.

- Industry Leadership: By showcasing the benefits of listening to customer needs and implementing tailored solutions, there is an opportunity to strengthen Laticrete’s position as a leader in the construction industry. This project underscores the importance of developing robust and flexible industrial systems, setting a benchmark for future projects.

CONCLUSION:

The challenge of enhancing Laticrete’s palletizing machine was successfully addressed through the implementation of event-driven logic, resulting in significant improvements in system throughput and operational efficiency. The success of this project highlights the effectiveness of adaptable control systems and the importance of customer-centric solutions. Looking ahead, there are substantial opportunities to replicate these successes across other plants and continue driving innovation in industrial automation.

Our expert team is here to help you implement the best solutions tailored to your unique needs. Find out more about our Automation and Manufacturing solutions.