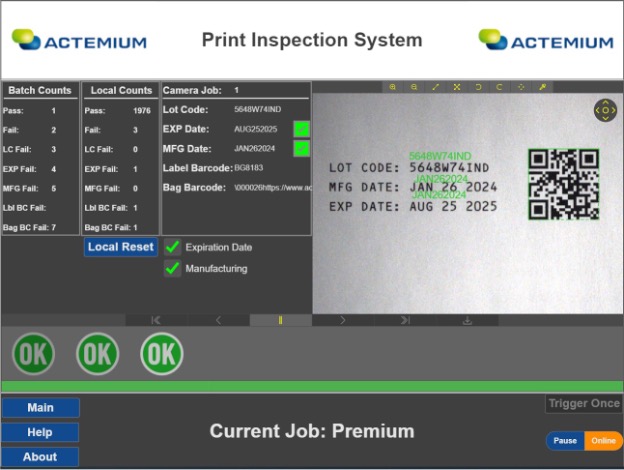

The Machine Vision Support Plan boosts reliability, quality, and performance for your inspection systems. Regular maintenance and data backups ensure consistent high-quality inspections, reduce downtime, and extend equipment lifespan. Performance tracking and obsolescence reviews help optimize operations and keep your technology up-to-date. Comprehensive reporting offers actionable insights for informed decisions, helping you maintain excellence in production quality and efficiency.

What We Will Deliver

A detailed report for ongoing use and comparison, offering a comprehensive view of your system’s performance, quality metrics, maintenance actions, and lifecycle status. Regular updates allow you to track trends, manage improvements, and ensure reporting accuracy, supporting proactive system management and long-term reliability of your machine vision systems.

-

PREVENTATIVE MAINTENANCE & INSPECTION

Verify stability, cleanliness, and alignment of camera and lighting system to ensure optimal performance and reliability.

-

DATA BACKUP & COMPARISON

Perform full system backups; Archive and compare data to maintain consistency and integrity.

-

IMAGE QUALITY ANALYSIS

Evaluate positioning, lighting, and focus; Conduct calibration checks to ensure alignment with baseline standards.

-

PERFORMANCE MONITORING

Track and analyze system performance. Review rejection rates and types; Identify trends and deviations from baseline performance.

-

OBSOLESCENCE MANAGEMENT

Stay ahead of technology life cycle changes by assessing and managing the lifecycle status of key system performance.

-

COMPREHENSIVE REPORTING

Maintain transparency and informed decision-making with regular updates and detailed reports.